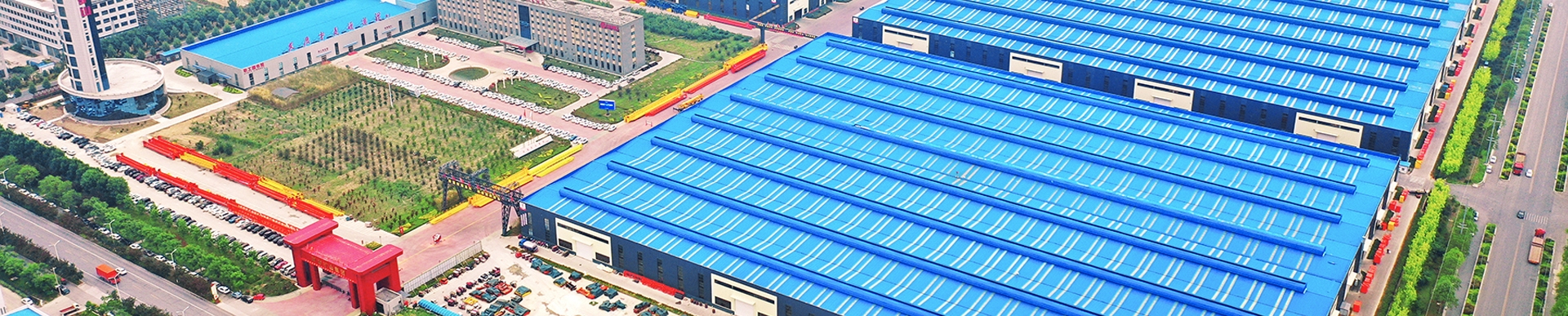

Zomax crane, with a registered cap of over RMB 117.7 million, more than 3,500 sets of advanced processing equipment, now has a total industrial area of more than 400 acres and over 4700 employees.

In 2023, Zomax Crane achieved a production and sales volume exceeding 110,000 units serving over 7,000 clients . The industry span a wide range, including aerospace, automotive, shipbuilding, steel smelting, petrochemicals, electronics, electrical equipment, water

Our mission is “offer material handling solutions with relentless reliability, maximum safety and innovation“. To achieve this, we continuously invest in our team, carrying out on-going product innovation and providing a spectrum of consulting and services.

Some of the best-known companies in the world choose Zomax. Up to now, we have already exported cranes to more than 50 countries.

Insisting the concept of “Sincerity, reliability and respect”,Zomax is on the path to becoming a world-renowned brand.