Crane rails are important devices that enable cranes to move horizontally within the work area for precise load handling and position control.

They have different shapes and fit various applications. Choosing the right rail depends on factors like the crane’s load capacity, installation conditions, and operating environment. The rail head width should match the crane wheel size.

Zomax can offer the following rails:

We also provide other rail types like JIS standard, UIC standard, based on client needs.

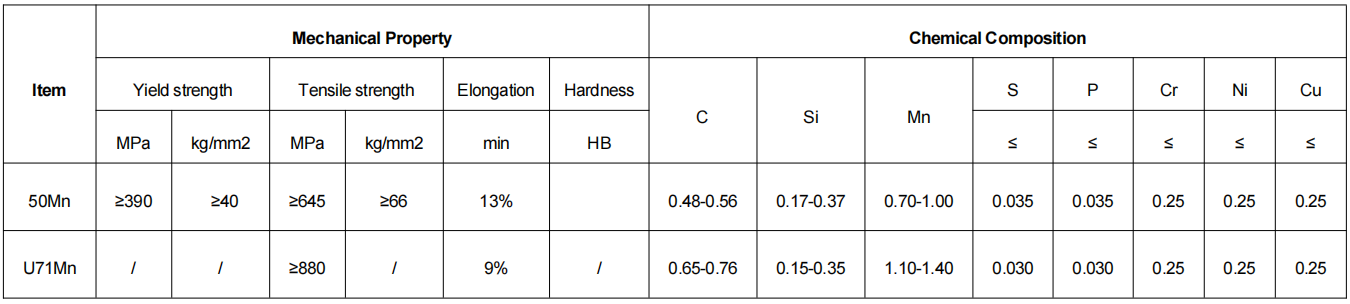

Steel grades are produced to various qualities and specifications as our clients require.

Zomax technical support can ensure that every rail we deliver provides optimal performance throughout its service life.

Standard rail lengths are furnished from 6 to 24 meters. Other lengths are available upon request.

Length customization is available to facilitate container loading.

45 degree cutting for the both ends is available.

Drilling holes at both ends is available as an optional service.

We also supply rail processing, like welding, milling, special profile processing, etc.

Our engineers assist customers in designing and building crane movement line according to specific requirements.

A, P, and QU rails are ideal for heavy-duty, high-frequency applications that demand standardization, durability, and long-term cost efficiency. They are especially suited for settings requiring high safety standards and compatibility with standard components.

P-type rails are now widely used across various applications, including rail cranes and trolleys. The rail features a convex top and a flat plate of specific width at the base, enhancing the contact area with the foundation. Its I-shaped cross-section provides excellent bending strength.

Rectangular Rail: This type is suitable for custom or low-load applications, unique design requirements, short-term projects, or situations where initial cost savings are a priority.

A, P, and QU rails are ideal for heavy-duty, high-frequency applications that demand standardization, durability, and long-term cost efficiency. They are especially suited for settings requiring high safety standards and compatibility with standard components. P-type rails are now widely used across various applications, including rail cranes and trolleys. The rail features a convex top and a flat plate of specific width at the base, enhancing the contact area with the foundation. Its I-shaped cross-section provides excellent bending strength.

Rectangular Rail: This type is suitable for custom or low-load applications, unique design requirements, short-term projects, or situations where initial cost savings are a priority.

Zomax have extensive experience in exporting crane rail systems,providing spare parts, expert installation, and maintenance support.

Spare Parts: supply suitable rail parts, like fish plates, rail clips, bolts and nuts, for timely replacement of damaged or lost components to reduce downtime and improve efficiency.

Installation: Comprehensive video instructions and remote support if needed.

Maintenance: Detailed guidelines and free consultation services for any product-related issues.

In order to better serve the diverse needs of customers, our technical team is available to provide expert advice and support, helping each customer to optimize their rail selection to minimize life cycle costs.

+86 373 8735088